Equipment Monitoring with Preventive and Calibration Report Generation

Abstract

Table of Contents

Equipment is essential for companies that heavily rely on machinery to operate a business. Thus, they must closely monitor the conditions of the machines. Machinery malfunction can severely impede a company’s efficiency and operations, it is in the best interests of management to ensure that equipment works correctly and has the longest possible service life.

The advent of computer technologies dramatically changed how businesses conduct day-to-day operations and transactions. Computerized systems and applications streamline different business operations which increases business efficiency. Manual processes of business operations became obsolete and were replaced with technology-assisted systems.

The researchers conducted the study to assess the methods used by companies in monitoring and preventing their equipment from wearing out. According to the data gathered by the researchers, some companies or business organizations still face problems in efficiently monitoring their equipment. They are in continuous search for the right and efficient software that could assist them in monitoring and preventing machines from unexpected malfunctions.

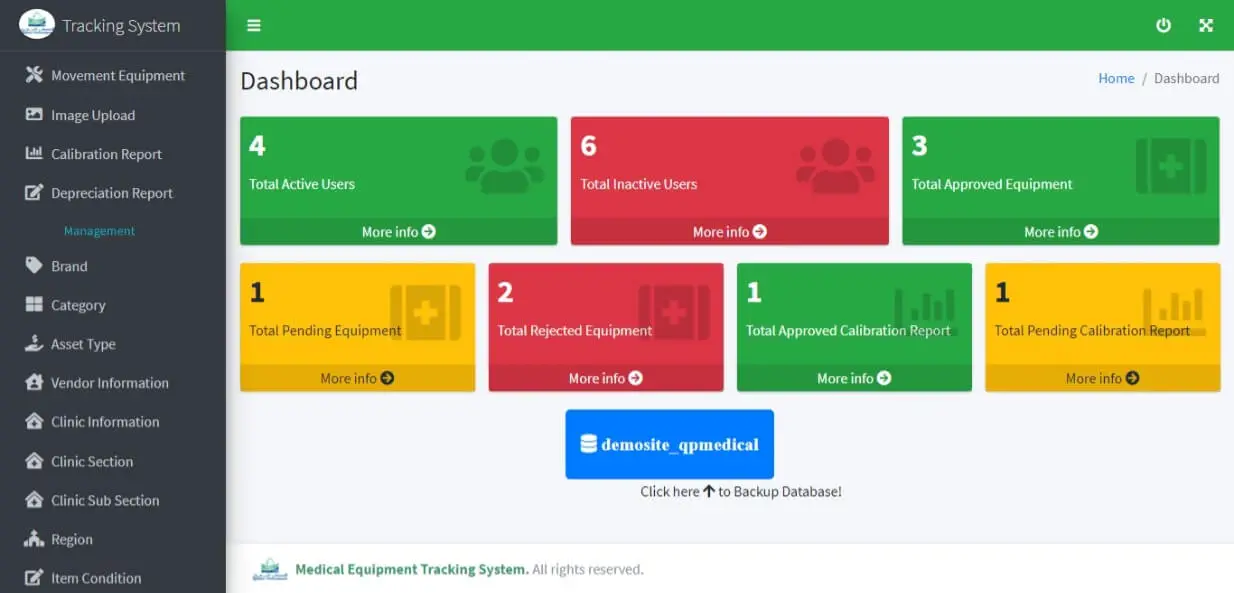

The capstone project, “Equipment Monitoring with Preventive and Calibration Report Generation” is designed to automate the process of monitoring equipment. The system is designed to automatically generate preventive and calibration reports for the equipment.

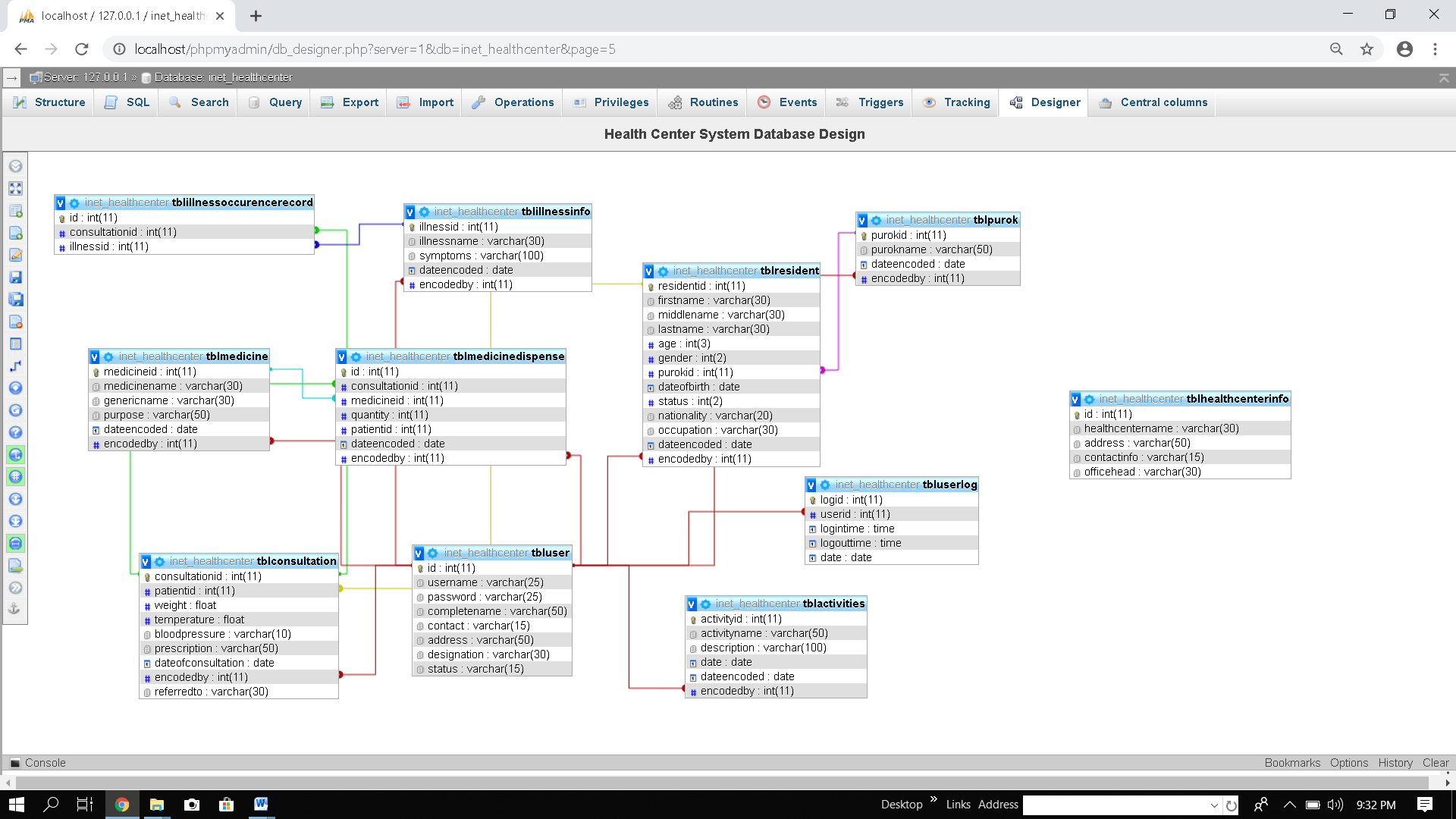

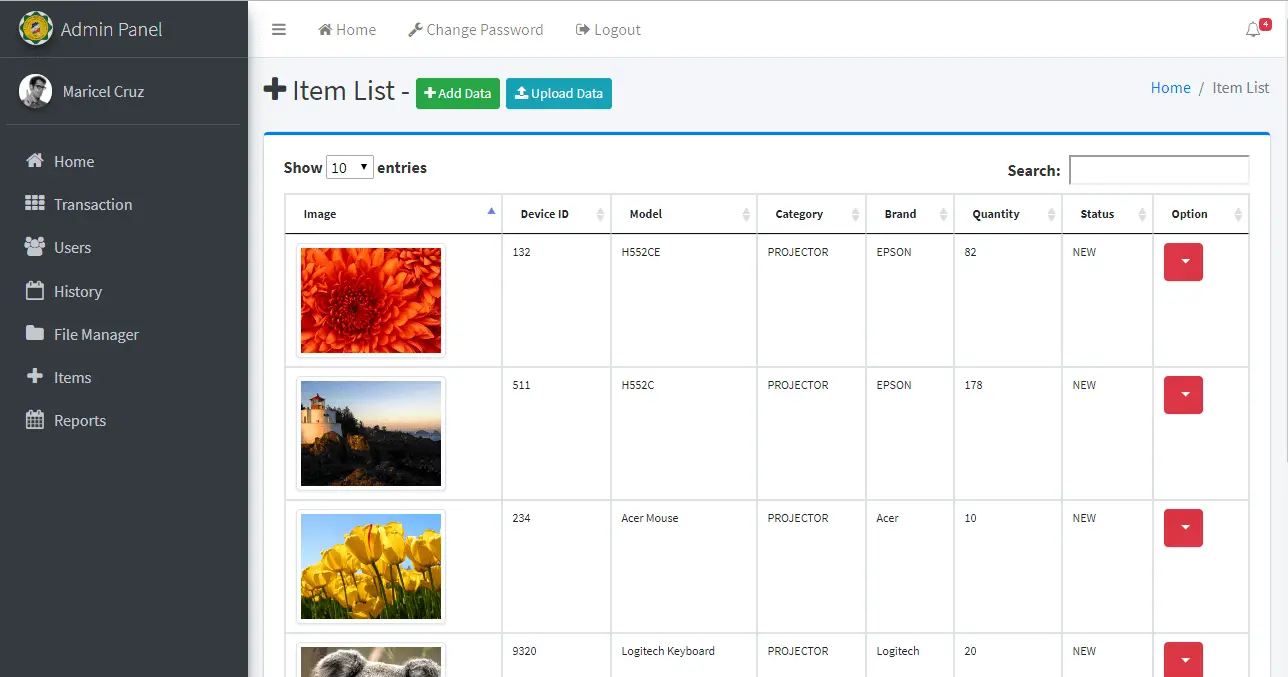

The core functions of the system are recording and storing equipment information, equipment monitoring, and report generation.

The implementation of the system will help companies closely monitor their equipment. Manufacturers can detect signs of degradation before it becomes a problem, leading to a reduction in downtime and the amount of maintenance required. The developed system is efficient to assist companies in preventing their equipment from wearing out.

Introduction

The capstone project, “Equipment Monitoring with Preventive and Calibration Report Generation” allows companies or organizations to actively monitor the condition of the equipment to produce real-time information about the conditions of the equipment. The system will also generate preventive and calibration reports.

Preventing equipment failure is a top priority for any company that depends heavily on it. Since a machinery malfunction can severely impede a company’s efficiency and operations, it is in the best interests of management to ensure that equipment works correctly and has the longest possible service life. However, without proper tools to monitor the condition of the equipment prevention will be hard to achieve. Organizations highly need advanced technology to monitor their equipment to prevent it from wearing out and breaking down.

Proposed Solution

The researchers of the study proposed Equipment Monitoring with Preventive and Calibration Report Generation as a solution for the aforementioned concerns. The system will help organizations monitor what is happening with the equipment and manufacturers can detect signs of degradation before it becomes a problem, leading to a reduction in downtime and the amount of maintenance required. The system is efficient to use to assist organizations in preventing their equipment from wearing out.

Objectives of the Study

General Objective – the primary purpose of the project is to design and develop an Equipment Monitoring with Preventive and Calibration Report Generation

which allows organizations or companies to keep track of the condition of their equipment.

The project specifically aims the following objectives:

1. To develop a system that will prevent equipment failure.

2. The system will help organizations or companies reduce their maintenance cost.

3. The system will automatically generate preventive and calibration reports.

4. The system will let organizations or companies conveniently monitor their equipment.

5. To design a system that is efficient and reliable to use.

Scope of the Study

This paper covers the process of developing an Equipment Monitoring with Preventive and Calibration Report Generation system. The system is limited only to monitoring equipment and machinery. The system will provide a real-time report about the status and conditions of the equipment as well as appropriate preventive and calibration measures. Companies and maintenance staff will serve as respondents to the study.

Significance of the Study

The success of the study is deemed beneficial to the following individuals or groups:

Companies/Organizations. The system will help them prevent significant financial losses due to the failure of equipment. The system will generate preventive and calibration reports for easy monitoring.

Maintenance Department. The system will ease up their work in monitoring the conditions of the equipment. They would not need to manually carry out their works.

Researchers. The researchers of the study will gain more knowledge and experience in developing programs.

Future Researchers. The study will serve as their basis in pursuing their version of the project.

Conclusion

Equipment maintenance is an essential process for companies to boost operational efficiency and financial stability. It is important to ensure that the equipment is well maintained, works correctly, and has the longest possible service life. The researchers developed an automated system that allows the company’s maintenance department to electronically monitor equipment. Based on the result of the study, the developed system met the needs and requirements of the respondents and target end-users.

The result of the study showed that the developed system will seamlessly aid the process of monitoring equipment that operates the business. Base on the result, the researchers concluded that the developed system is effective in ensuring that the equipment will not malfunction unexpectedly. The maintenance department can easily and actively monitor the equipment. Also, the maintenance department staff can obtain accurate reports on proper preventive and calibration of the equipment. These reports are vital in prolonging the life of the machines and their functionality.

Recommendations

Based on the positive result of the study, the researchers highly recommend that companies or business organizations integrate the system in their business operations. The developed system is efficient and dependable in terms of monitoring equipment. The researchers highlight the importance of the end-users having enough knowledge about the features and how the system works to properly use it.

The following are the specific recommendations of the researchers:

1. The company’s maintenance department should install the system to easily, closely, and efficiently monitor every piece of equipment.

2. Companies should adopt the use of technology to improve operational efficiency.

3. The implementation of the developed system will allow companies to save money and time in maintaining equipment.

4. The developed system is highly recommended for it will make equipment monitoring easy, convenient, and efficient.

You may visit our facebook page for more information, inquiries, and comments.

Hire our team to do the project.