Inventory System Work Breakdown Structure

Introduction

Table of Contents

Managing an inventory system can feel like juggling countless tasks—tracking stock, coordinating user roles, generating reports, and ensuring system reliability. Without a clear plan, even the most well-intentioned projects can spiral into chaos. That’s where a Work Breakdown Structure (WBS) comes in, transforming complexity into clarity. In this post, we’ll explore how a WBS can streamline the development of an Inventory System, making it easier for project managers, developers, and stakeholders to achieve success.

An Inventory System is a software solution designed to manage stock, process orders, and track transactions efficiently. It involves diverse functionalities, such as allowing admins to configure settings, inventory managers to update stock levels, and auditors to verify transactions. With multiple user roles and intricate features, the project demands precise organization. A WBS is the perfect tool to break this complexity into manageable tasks, ensuring every team member knows their responsibilities.

The purpose of this post is to show you how a Work Breakdown Structure can simplify Inventory System development. We’ll define what a WBS is, highlight its benefits, and provide a detailed example based on the system’s user roles (e.g., Admin, Inventory Manager, Staff, Auditor) and their accessible features. Whether you’re a project manager overseeing a warehouse system or a developer building an e-commerce inventory tool, this guide will help you harness the power of WBS to deliver results.

By the end, you’ll have a clear roadmap for organizing your Inventory System project, complete with a practical WBS example and steps to create your own. Ready to turn your project challenges into a structured success story? Let’s dive into the world of Work Breakdown Structure and see how it can revolutionize your Inventory System development!

What is a Work Breakdown Structure?

A Work Breakdown Structure (WBS) is a project management tool that breaks a complex project into smaller, actionable deliverables. Think of it as a blueprint for building a house, where the project (the house) is divided into manageable parts like foundation, walls, and roof. Each part is further split into tasks, ensuring clarity and focus. For an Inventory System, a WBS organizes tasks like user management, stock tracking, and reporting, making the project less daunting.

At its core, a WBS consists of deliverables (major project components), tasks (specific actions), and sub-tasks (detailed steps). It plays a critical role in project management by clarifying scope, organizing work, and improving team coordination. Without a WBS, teams risk miscommunication or overlooked tasks, especially in complex projects like an Inventory System.

For an Inventory System, a WBS is invaluable due to its multiple stakeholders and functionalities. With roles like Admins configuring permissions, Inventory Managers monitoring stock, and Auditors reviewing logs, the system involves diverse tasks. A WBS ensures each role’s responsibilities are clearly defined, preventing overlap or confusion. For example, it separates “Update Stock Levels” for Inventory Managers from “Set Permissions” for Admins, streamlining workflows.

By providing a hierarchical view of the project, a WBS acts like a recipe, breaking the Inventory System into bite-sized pieces. Whether you’re managing a retail warehouse or an e-commerce platform, understanding WBS is the first step to mastering your project’s complexity.

Benefits of Using WBS for an Inventory System

A Work Breakdown Structure (WBS) is a game-changer for Inventory System projects, offering clarity and efficiency in managing complex tasks. By breaking the project into manageable deliverables, a WBS addresses the unique challenges of inventory management. Here are four key benefits, each tailored to the Inventory System context:

- Enhanced Task Clarity: A WBS organizes tasks by user roles, ensuring everyone knows their responsibilities. For example, it separates Admin tasks like “Configure Categories” from Staff tasks like “Request Items,” preventing confusion and ensuring focus. This clarity is crucial for an Inventory System, where diverse roles like Auditors and Inventory Managers handle distinct functions.

- Improved Resource Allocation: By mapping out tasks, a WBS helps allocate time, budget, and personnel effectively. For instance, assigning “Update Stock Levels” to Inventory Managers ensures they have the tools and time needed, while Admins focus on system settings. This prevents resource waste in a project with multiple functionalities like stock tracking and reporting.

- Risk Mitigation: A WBS identifies potential bottlenecks early, reducing risks. For an Inventory System, it ensures tasks like “Monitor Expiry Dates” are assigned to Inventory Managers, preventing stock spoilage. By clarifying dependencies (e.g., “Verify Stock Movement” follows “Update Stock Levels”), the WBS minimizes errors and delays.

- Better Stakeholder Alignment: A WBS fosters collaboration by providing a shared project view. For example, Auditors can see their role in “View Transaction Logs” aligns with Admins’ “Generate Reports,” ensuring all stakeholders are on the same page. This alignment is vital for Inventory System projects involving cross-functional teams.

These benefits make a WBS indispensable for Inventory System development, whether for a small retail setup or a large warehouse. By providing structure and foresight, a WBS ensures your project stays on track, delivering a robust system that meets user needs.

Example Work Breakdown Structure for an Inventory System

A Work Breakdown Structure (WBS) for an Inventory System organizes its complexity by breaking it into user roles and their tasks. Below, we present a detailed WBS, including a PlantUML script, a textual hierarchy, and an explanation of each component, highlighting how it ensures clear task delegation.

PlantUML Script

@startwbs skinparam backgroundColor #FFFFFF skinparam defaultTextAlignment left skinparam Shadowing false skinparam LineThickness 2.0 * Inventory System ** Admin *** Manage Users **** Add/Edit/Delete Users **** Assign Roles *** Manage Inventory **** Add/Edit/Delete Items **** Set Reorder Levels **** Generate Reports *** System Settings **** Configure Categories **** Set Permissions ** Inventory Manager *** View Inventory **** Check Stock Levels *** Update Stock Levels **** Record Stock Updates *** Monitor Expiry Dates **** Flag Expired Items *** Generate Inventory Reports **** Create Stock Reports ** Staff/User *** View Available Items **** Browse Catalog *** Request Items **** Submit Request *** Track Request Status **** View Request Updates ** Auditor *** View Transaction Logs **** Review Logs *** Access Inventory Reports **** Analyze Reports *** Verify Stock Movement **** Audit Discrepancies @endwbs

WBS Hierarchy and Explanation

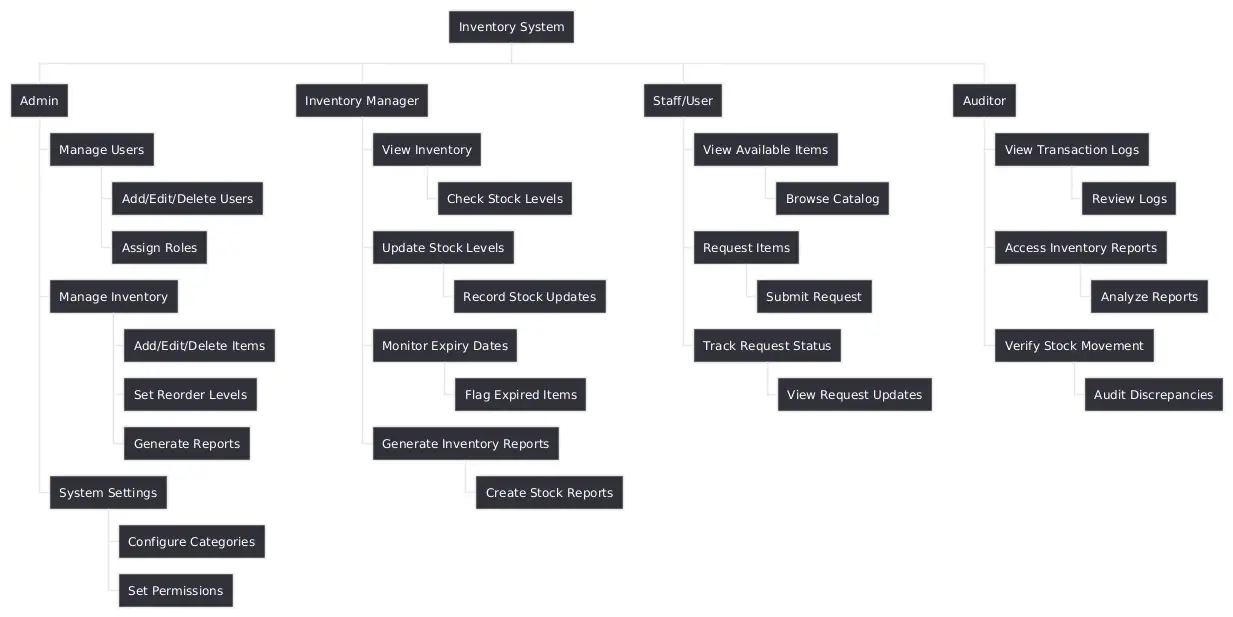

The WBS starts with the Inventory System as the root, branching into four user roles: Admin, Inventory Manager, Staff/User, and Auditor. Each role has specific deliverables, broken into tasks and sub-tasks, visualized in the PlantUML diagram with bold lines for clarity.

- Admin: This branch focuses on system-wide management. “Manage Users” includes tasks like “Add/Edit/Delete Users” and “Assign Roles,” ensuring user access is controlled. “Manage Inventory” covers “Add/Edit/Delete Items” and “Set Reorder Levels,” critical for stock control, and “Generate Reports” for insights. “System Settings” includes “Configure Categories” (e.g., product types) and “Set Permissions,” ensuring system security. The WBS clarifies Admins’ broad responsibilities, preventing overlap with other roles.

- Inventory Manager: This role centers on stock oversight. “View Inventory” includes “Check Stock Levels,” while “Update Stock Levels” involves “Record Stock Updates.” “Monitor Expiry Dates” with “Flag Expired Items” prevents spoilage, and “Generate Inventory Reports” creates “Stock Reports” for decision-making. The WBS ensures Inventory Managers focus on operational tasks.

- Staff/User: This branch covers end-user interactions. “View Available Items” allows “Browse Catalog,” “Request Items” involves “Submit Request,” and “Track Request Status” includes “View Request Updates.” The WBS streamlines user tasks, enhancing system usability.

- Auditor: Focused on compliance, this role includes “View Transaction Logs” (“Review Logs”), “Access Inventory Reports” (“Analyze Reports”), and “Verify Stock Movement” (“Audit Discrepancies”). The WBS isolates auditing tasks, ensuring accountability.

The PlantUML diagram’s hierarchical structure visually separates roles and tasks, making it easy to understand responsibilities. By organizing the Inventory System’s complexity, this WBS ensures efficient task delegation and project success

How to Create a WBS for Your Inventory System

Creating a Work Breakdown Structure (WBS) for your Inventory System is a straightforward process that brings clarity to your project. By following these five steps, you can develop a WBS that organizes tasks, aligns teams, and drives success. Here’s how to do it, with tips tailored to Inventory System development:

- Define the Project Scope: Start by outlining the Inventory System’s objectives, such as managing stock, processing orders, and ensuring compliance. Identify key stakeholders (e.g., Admins, Inventory Managers, Auditors) and deliverables (e.g., user management, reporting). For example, decide if the system covers retail, warehouse, or e-commerce inventory. A clear scope prevents scope creep and sets the WBS foundation.

- Identify Major Deliverables: Break the project into core components based on functionalities or user roles. For an Inventory System, deliverables might include “User Management,” “Inventory Tracking,” “Order Processing,” and “Auditing.” These align with roles like Admin (for user management) or Auditor (for auditing). List deliverables that reflect the system’s goals, ensuring they’re measurable.

- Break Deliverables into Tasks: Divide each deliverable into smaller tasks. For “Inventory Tracking,” tasks might include “View Inventory,” “Update Stock Levels,” and “Monitor Expiry Dates.” For “User Management,” include “Add/Edit/Delete Users” and “Assign Roles.” Keep tasks specific and actionable, ensuring they’re assignable to team members. This step adds granularity to the WBS.

- Assign Responsibilities: Map tasks to roles or team members. For example, assign “Update Stock Levels” to Inventory Managers and “Set Permissions” to Admins. Ensure each task has a clear owner to avoid confusion. For an Inventory System, consider the skills needed—e.g., Auditors need access to transaction logs, while Staff need user-friendly interfaces. This step enhances accountability.

- Review with Stakeholders: Share the WBS with stakeholders (e.g., developers, managers, clients) to validate tasks and dependencies. For instance, confirm that “Generate Reports” supports both Admins and Auditors. Refine the WBS based on feedback, ensuring it aligns with project goals. Tools like PlantUML can visualize the WBS for stakeholder reviews.

Tips for Success: Use tools like PlantUML for visualization, MS Project for scheduling, or Trello for task tracking. Tailor the WBS to your Inventory System’s context—e.g., include “Sales Order Processing” for e-commerce systems. Start simple and iterate as the project evolves. By following these steps, you’ll create a WBS that transforms your Inventory System into a well-organized, achievable project.

Summary and Conclusion

A Work Breakdown Structure (WBS) is your key to mastering Inventory System projects. This post defined WBS as a hierarchical tool that breaks complex projects into manageable tasks, ensuring clarity and coordination. We explored its benefits—task clarity, resource allocation, risk mitigation, and stakeholder alignment—all tailored to the Inventory System’s diverse roles and functionalities. Our example WBS, visualized with a PlantUML script, showcased how Admins, Inventory Managers, Staff, and Auditors can work seamlessly by organizing tasks like “Update Stock Levels” and “Verify Stock Movement.” Finally, we provided a five-step guide to create your own WBS, empowering you to tackle your project with confidence.

The Inventory System Work Breakdown Structure is more than a tool—it’s a roadmap to success, ensuring every task aligns with your project’s goals. Whether you’re managing a retail warehouse or an e-commerce platform, a WBS can transform chaos into clarity. Ready to get started? Create your own WBS using PlantUML, experiment with tools like Trello, or share your experiences in the comments below. How will you use WBS to streamline your Inventory System? Let’s make project management effortless together!

You may visit our Facebook page for more information, inquiries, and comments. Please subscribe also to our YouTube Channel to receive free capstone projects resources and computer programming tutorials.

Hire our team to do the project.